Basic principles of physiology and flock management converge to achieve the genetical potential of current broiler strains irrespective of harvest weight. Care in selection, installation, operation and maintenance of watering systems contributes to optimal live bird parameters, quality, yield and returns to both contractor and integrator.

Basic principles of physiology and flock management converge to achieve the genetical potential of current broiler strains irrespective of harvest weight. Care in selection, installation, operation and maintenance of watering systems contributes to optimal live bird parameters, quality, yield and returns to both contractor and integrator.

- How Broilers Regulate Water Intake

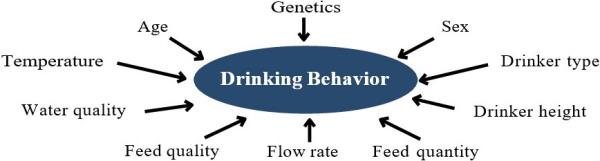

Birds drink when they are thirsty. The hormonal and neural mechanisms involved in thirst have developed through the evolution of chickens over millennia. More recently intensive index selection for commercial traits favoring rapid growth and breast yield has influenced behavior and water requirement. The stimulus to drink is initiated by baroreceptors sensitive to blood pressure and osmoreceptors that respond to changes in the chemical composition of blood. Thirst reflects the interpretation of signals received from receptors that are processed by centers in the brain that encourage drinking.

In contrast to mammals, chickens have two added complications in regulation of water intake. Heat is lost by evaporative cooling only from respiratory surfaces as skin is insulated by feathers. Avian kidneys are relatively inefficient, consistent with their reptilian ancestry. The glomeruli, microscopic structures in the kidney responsible for filtration are less numerous than in mammals and are smaller and relatively inefficient, placing an additional burden on the neural and hormonal factors that regulate thirst.

|

When birds are subjected to high ambient temperature, respiratory rate increases to enhance evaporation of water from the surfaces of the trachea, pharynx and oral cavity. With the change in state from liquid to vapor, latent heat is lost, effectively cooling the bird. This process requires water drawn from the blood necessitating replacement from extracellular water. The resultant changes in blood composition stimulate thirst. Evaporative cooling results in increased water consumption by the flock that is evident when comparing water meter readings against ambient temperature.

With an understanding of factors that influence thirst, it is self-evident that simple rule-of-thumb formulas relating to flow-rate of nipple type drinkers are simplistic, meaningless and potentially counterproductive. Water intake by any flock is influenced by age, strain, growth rate and environmental conditions in the house. These include ventilation settings in relation to temperature, humidity and ammonia content of air. It is not possible to induce broilers to eat more than their physiological requirements by attempt to increase water intake through raising water pressure in drinker lines.

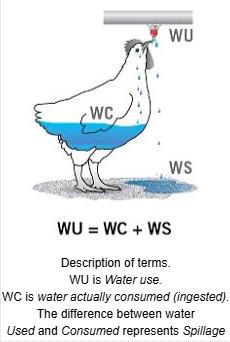

- Water Use Compared to Actual Intake

It is important to distinguish between water use as measured by the volume of water passing through a house meter and the intake represented by the actual volume of water swallowed and hence ingested. The difference between use and intake represents spillage. A drinker with an excessive discharge of water when activated by the bird will indeed satisfy thirst. It is inevitable that water that is not swallowed due to limitations of the capacity of the oral cavity will be spilled on to the litter. The ability of various substrates including wood shavings and rice hulls to absorb spillage is limited especially with the reality of leakage from imperfectly designed or operated nipples.

The rate of removal of water from litter is a function of the temperature and humidity in the house in relation to the operation of the ventilation system. At humidity levels below 50 percent and with a minimum ventilation rate of 1cfm per pound body weight, excess moisture will be removed from litter and hopefully under the drinker lines where the flock congregates. In the event of excessive spillage during drinking and any leakage from drinkers saturation of litter will occur. This is especially evident under conditions of high humidity coupled with low temperature or when suboptimal ventilation rates are applied to conserve gas.

- Management of Watering Systems

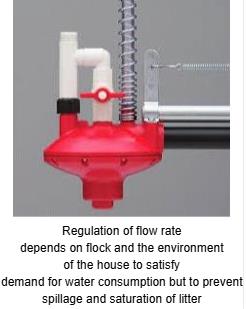

Many within the chicken industry emphasize the importance of a high static-flow rate (excessive pressure to release water) from nipples, usually expressed as milliliters per minute. Simple values relating to age of a flock are essentially meaningless in the context of satisfying thirst. A static flow rate does not correlate to the way in which a bird actually interacts with a nipple drinker. Chickens peck at trigger pins to receive a small release of water, most of which should be swallowed. Ideally the quantity of water ingested should be adequate to satisfy thirst but not so high that any appreciable quantity is spilled. Nipple drinkers should supply an adequate, but not excessive, quantity of water as the bird pecks at the trigger. This satisfies requirements for growth and prevents spillage on to litter.

Many within the chicken industry emphasize the importance of a high static-flow rate (excessive pressure to release water) from nipples, usually expressed as milliliters per minute. Simple values relating to age of a flock are essentially meaningless in the context of satisfying thirst. A static flow rate does not correlate to the way in which a bird actually interacts with a nipple drinker. Chickens peck at trigger pins to receive a small release of water, most of which should be swallowed. Ideally the quantity of water ingested should be adequate to satisfy thirst but not so high that any appreciable quantity is spilled. Nipple drinkers should supply an adequate, but not excessive, quantity of water as the bird pecks at the trigger. This satisfies requirements for growth and prevents spillage on to litter.

Managing a watering system to achieve an undesirably high flow rate, causing excess spillage is analogous to working on a hot day in a garden and drinking from a hose. The flow rate from the nozzle will be too high in relation to the volume that can actually be swallowed over a few seconds. Although thirst is satisfied there is considerable spillage. This may be inconsequential standing on a lawn but in the context of broiler growing, spillage saturates litter in a poultry house with adverse effects on health and quality.

The correct function of drinking systems should not be measured by static water flow rate but by dynamic release that conforms to the pattern of drinking conditioned by volume of the oral cavity. The return over production costs for a flock is influenced by adequate water and feed intake and freedom from erosive intestinal and respiratory diseases, resulting in optimal growth and product quality.

- The Consequences of Wet Litter

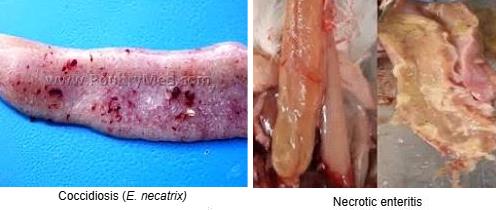

High moisture levels in litter extending to areas of saturation is problematic for broiler flocks. Wet bedding is invariably associated with respiratory, intestinal and skin conditions that detract from optimal growth and that compromise quality.

- Intestinal conditions that are adversely affected by wet or damp litter include coccidiosis and clostridial enterotoxemia (necrotic enteritis and hepatitis). Appropriate control of litter moisture is extremely important in drug-free growing systems. Elimination of chemical feed-additives including antibiotics and coccidiostats presumes greater attention to management of ventilation and watering systems to prevent excess litter moisture. Feed additives used in conventional production suppress intestinal proliferation of Clostridium and block stages in the life cycle of coccidiosis parasites.

- Ammonia is liberated from damp and wet litter. This is the result of bacterial degradation of uric acid excreted by the flock. Ammonia irritates the respiratory mucosa exacerbating the effects of respiratory pathogens including infectious bronchitis and laryngotracheitis viruses. There is ample evidence to show that flocks subjected to levels of atmospheric ammonia exceeding 25 ppm at bird’s head height for prolonged periods have lower growth rates and higher mortality than when reared at lower levels of atmospheric ammonia.

- Skin is adversely affected by wet litter and ammonia. Proliferation of Clostridium spp. in damp litter contributes to gangrenous dermatitis. Wet litter with liberation of ammonia predisposes to “hock burn” and pododermatitis restricting growth rate and reducing the value of feet for export.

- Wet litter increases proliferation of Salmonella spp. and Campylobacter spp. These foodborne pathogens are ingested by the flock, colonizing the intestinal tract and coating feathers. This increases the level of fecal excretion, contaminating transport modules, scald tanks, defeathering and E-line equipment, contributing to potentially high levels of pathogens on products. Wet litter favors persistence and proliferation of bacterial foodborne pathogens reflecting adversely on compliance with USDA-FSIS standards.

Selection and management of watering systems is integral to achieving optimum return from flocks and should be based on applying appropriate pressure settings and operation of ventilation installations.