EGG-NEWS welcomes the Vencomatic Group as a sponsor. The Company was founded in 1983 by the van de Ven family in their Eersel, location in the Netherlands. The Group has expanded to include major operating segments comprising Agro Supply, Prinzen, Van Gent and Vencomatic. Vencosteel is a dedicated supplier of metal components including stainless and specialty steel with an output of 6,500 tons annually. The Vencomatic Group operates subsidiaries in the U.S. (Adel, IA), in Sao Paulo State (Brazil) and in France, Spain, the U.K., China and Malaysia.

EGG-NEWS welcomes the Vencomatic Group as a sponsor. The Company was founded in 1983 by the van de Ven family in their Eersel, location in the Netherlands. The Group has expanded to include major operating segments comprising Agro Supply, Prinzen, Van Gent and Vencomatic. Vencosteel is a dedicated supplier of metal components including stainless and specialty steel with an output of 6,500 tons annually. The Vencomatic Group operates subsidiaries in the U.S. (Adel, IA), in Sao Paulo State (Brazil) and in France, Spain, the U.K., China and Malaysia.

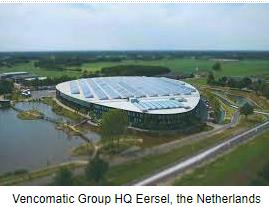

The company posted revenue of $175 million worldwide in 2023 and has 500 employees interacting with 100 suppliers and strategic partners worldwide. The Headquarters Complex in Eersel is uniquely shaped to resemble an egg, recognizing the focus of the company

Vencomatic pullet rearing systems include:-

- The multi-tier Unistart that simplifies vaccination and handling and allows complete visual observation of flocks contributing to uniformity in growth and development.

- The Bolegg starter system is designed for compatibility with the Bolegg aviary. Features of this system include the winchable platforms for water and feed to train flocks.

- The Jump-Start system allows chicks to be placed on slats with access to feed and water. Feeding and drinking levels are raised as pullets grow to encourage development of muscles and balance to allow subsequent use of perches.

Vencomatic aviaries include:-

- The Bolegg Gallery aviary is a multi-tier system allowing natural behaviors. The gallery incorporates the Vencomatic laying nest with a tipping floor, Vencobelt egg collection and Vencoslat flooring.

- The Bolegg Terrace aviary system permits obstacle-free movement vertically within the system reducing cross transition between rows that uses energy and subjects hens to injury. The location of perches, drinkers and feeders allows the flock to move along the full length within the system.

Vencomatic developed the ECO heat exchanger to reduce energy requirements and to reduce feed intake under cold conditions.

The Meggsius range includes a machine-vision egg sorter that restricts introduction of leakers into the grader. The Meggsius belt control system accurately counts eggs and modulates conveyor speed to ensure optimal operation of graders and reduces rejects occurring during transit from houses to packing plants.